我们提供综合反向物流和循环经济服务,这些服务由我们的智能报告和测量工具、法规遵从性知识以及全球和区域业务提供支持。我们的行业专长确保客户可以自信地实现其可持续发展和业务目标,同时应对日益增长的、要求对物料的再利用或处置进行追溯的法规。

实施有效的循环经济解决方案战略需要利用数据的力量。

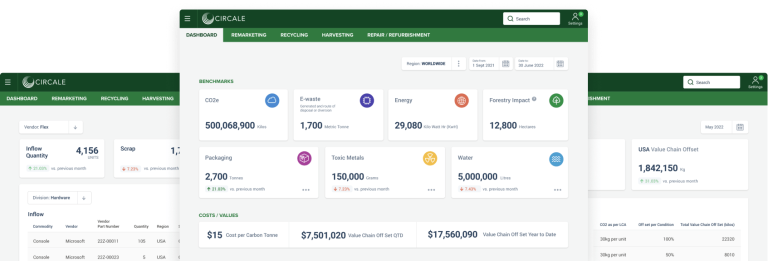

我们整套领先的财务和环境建模工具,包括屡获殊荣的伟创力 ECO2™ 和数字化循环平台 Circale,帮助客户量化我们的循环干预措施对于减少排放和提升资源效率的程度。

从企业、零售和消费渠道的退货产品中回收价值需要一个可靠的退货和筛选流程。

伟创力提供各种能力,以改善客户体验和退货可见性,同时最大程度提升价值回收。我们的服务包括客户退货流程管理、退货物流到收货,再到产品注册和筛选。

投资于维修和翻新能力以延长产品生命周期,已成为许多品牌的重要客户服务和可持续发展支柱。

凭借全球各地的可配置、可扩展作业,我们提供优质的技术维修和翻新服务,专为满足特定的交货期、服务和成本目标。我们的维修和翻新服务凭借对于产品和服务流程的洞察得以持续优化。

许多公司认识到产品在生命周期结束时剩余的内在价值。

此外,这些做法有助于减少废物和减排战略。我们所有工厂都提供零件收集服务和备件物流,并且与一个由众多回收合作伙伴组成的全球网络相连接。

电子商务战略已发展为包含循环商业模式,从而能够开辟新的收入来源、提高品牌声誉并满足日益增长的消费者需求。

作为可扩展的库存管理 B2B 市场,FreeFlow 能够简化再营销工作,以优化过剩库存。

FreeFlow 提供了能够最大程度实现回收并延长产品生命周期的渠道,同时通过严格的控制和透明度完全掌控定价和购买流程。

回收(尤其是电子废物回收)需要一家拥有监管行业专长、全球影响力、数据安全和可扩展性的合作伙伴,以获得减少废料带来的好处。

伟创力管理回收服务和回收供应商网络,以确保在推进可持续发展的同时,完全符合物料的监管链、产品零部件的可追溯性和知识产权保护。

艾伦·麦克阿瑟基金会:伟创力自 2021 年成为会员以来,加入该网络以推动利用最新循环经济、研究和趋势的解决方案。

了解有关线性拉伸缠绕膜的循环替代品的关键知识:伟创力与艾伦·麦克阿瑟基金会成员合作发布了拉伸缠绕膜替代项目 (SWAP),旨在应对拉伸缠绕膜产生的塑料废物。

反向物流协会:伟创力于 2024 年加入成为会员,参与一个由制造商、零售公司和第三方供应商组成的社区网络,在全球范围内开展教育并推广反向物流。

我们凭借循环经济解决方案和智能二氧化碳分析,在可持续服务类别中荣获可持续发展环境成就与领导力 (SEAL) 奖,突显了我们的领导力、创新和对可持续业务实践的承诺。

Flex ECO2™ 是我们专有的计算器,可帮助客户通过循环经济服务来衡量、报告和实现气候目标。因其卓越表现,我们荣获了“年度环境 + 能源最佳项目”奖。

Sorocaba 利用先进的制造技术,对电子废物进行改造,并通过维修、零部件和物料回收以及再循环,将重新利用的物料重新引入产品生命周期。这一长达十年的历程使 Sorocaba 获得了世界经济论坛授予的首个此类称号。

我们的退货流程管理确保每笔退货(无论是来自过剩、报废、渠道还是其他来源)都得到高效、安全的处理,并遵守适用的法律法规。从发起退货的那一刻起,我们就会管理整个流程和客户体验,确保产品快速、安全地在系统中移动,并让客户满意。

我们促进保修索赔的有序处理,以确保产品符合规定的条件,从而提高客户满意度、降低成本并确保合规。

我们提供快速、可靠且一致的筛选,包括保修内筛选、产品注册、测试和目视机械检查,以最大限度地降低因问题诊断不当而造成的成本。

我们的退换货解决方案能够实现及时周转,同时利用低成本地区进行维修和翻新,从而降低维修成本。

与伟创力合作,即可访问全面的反向物流和退货管理系统,所有这些都由一套可持续发展分析工具和服务提供支持,以解决复杂的产品退货和筛选以及客户服务运营问题。

一家生活方式客户有超过一百万台二手设备需要处理,在新市场中面临产品退货和反向物流挑战,并且需要对产品数据有更清晰的了解以支持回收物料的目标。

伟创力利用故障分析实验室的研究结果,提供新的产品设计、全球反向物流以及具有全面产品知识产权保护的端到端供应链解决方案。2023 年回收了超过 300 万台设备,从零件收集、分拣、再利用到重新整合到产品中进行转售的整个过程都可追溯。

帮助客户最大限度地减少新产品库存,同时创造新的收入来源和实现成本节约,特别是对于高价值或复杂的产品。

帮助客户享受零件回收等服务带来的可持续收益、满足不断变化的监管要求并量化环境节约以提高资源生产力。

对于一家希望推进循环经济进程的领先地板护理公司,伟创力实施了标准化售后解决方案,其中包括维修、翻新、退货、备件规划等。这种方法开辟了新的市场渠道,同时支持在美国和欧洲推行一种更具循环性的产品分销商业模式。结果,该公司减少了 7,650 吨二氧化碳当量,相当于让超过 4,000 辆汽车停驶一年。

为了确保及时维修和交付产品,我们投资了先进的 IT 系统来追踪维修过程中使用的组件。我们的集成 IT 系统实时更新维修状态,确保每个阶段的透明度和问责制。该系统还有助于管理库存,追踪所回收零件的可用性,并确保每项维修工作都使用正确的组件。

我们的集成物流能力确保修复的产品能够及时送达。我们了解尽量减少停机时间的重要性,并努力在不影响质量的情况下缩短周转时间。我们的物流团队与维修技术人员密切合作,协调产品从抵达我们工厂到最终交付的高效流转。

伟创力的资产回收解决方案在商品层面运作,确保高效回收有价值的组件和产品。

我们严格遵守物料监管链,提供完整的产品零部件可追溯性,在整个回收过程中确保透明度和责任可追溯性。

此外,我们优先考虑知识产权 (IP) 保护,在回收和再利用组件时保护敏感信息和专有技术。

一家消费设备客户需要更高效地管理租赁期满的商业 IT 设备库存,例如笔记本电脑、台式电脑和服务器。除了提供翻新服务外,伟创力还促进了二级市场的发展,翻新了超过 12,000 台设备,包括 3,900 个零件更换件。

该客户通过向新客户群体转售获得了新的收入来源。此外,我们的合作伙伴关系还推动了该客户的可持续发展目标,与生产新产品相比,预计可避免 75-80% 的二氧化碳排放。

零件回收使各公司能够采购和再利用零部件,以及将零部件重新引入供应链中。伟创力提供回收服务和备件物流,让客户可以访问我们的全球回收合作伙伴网络。通过从售后产品或过剩库存中回收零件,我们帮助客户确保其业务和供应链面向未来,同时实现可持续发展效益。

我们拥有跨行业专长和一流的回收合作伙伴,能够安全地处置回收电子产品中的危险物料,同时回收价值。我们有能力帮助客户应对数据采集和管理方面的挑战,确保遵守法规。

我们的资产回收和再利用服务的一个关键作用在于,客户能够通过自有渠道或与伟创力合作转售产品。这种方法不仅最大限度地提高了售后产品的价值,而且还支持一种更具可持续性的循环经济。

大部分已售产品不会回到卖家手中,这是实现循环的一个关键挑战。一种有效的策略是通过 PaaS 模式确保保留产品所有权。伟创力通过资产再利用和翻新来帮助促进 PaaS,使资产能够继续产生服务收入并实现可持续发展效益。伟创力处于独特的优势地位,能够在贴近市场的地方对设备进行测试、升级和翻新,实现快速且具有成本效益的周转,同时还能为未来的设计改进提供有价值的反馈。

作为可扩展的库存管理 B2B 市场,FreeFlow 能够简化再营销工作,以优化过剩库存。FreeFlow 提供了能够最大程度实现回收并延长产品生命周期的渠道,同时通过严格的控制和透明度完全掌控定价和购买流程。