As we mark the 50th anniversary of blood glucose meters (BGMs) this year, it’s a great time to celebrate how far this technology has come and its positive impact on people with diabetes. An estimated 463 million adults around the world were living with diabetes in 2019. And with this number expected to rise to 700 million by 2045, the need for monitoring will only increase.

More demand means higher consumer expectations. Digital technology now seamlessly integrates into almost every facet of daily life, and consumers will expect the same from their BGMs. Here’s a look at the evolution of this device that has helped so many people.

A (very) brief history of blood glucose meters

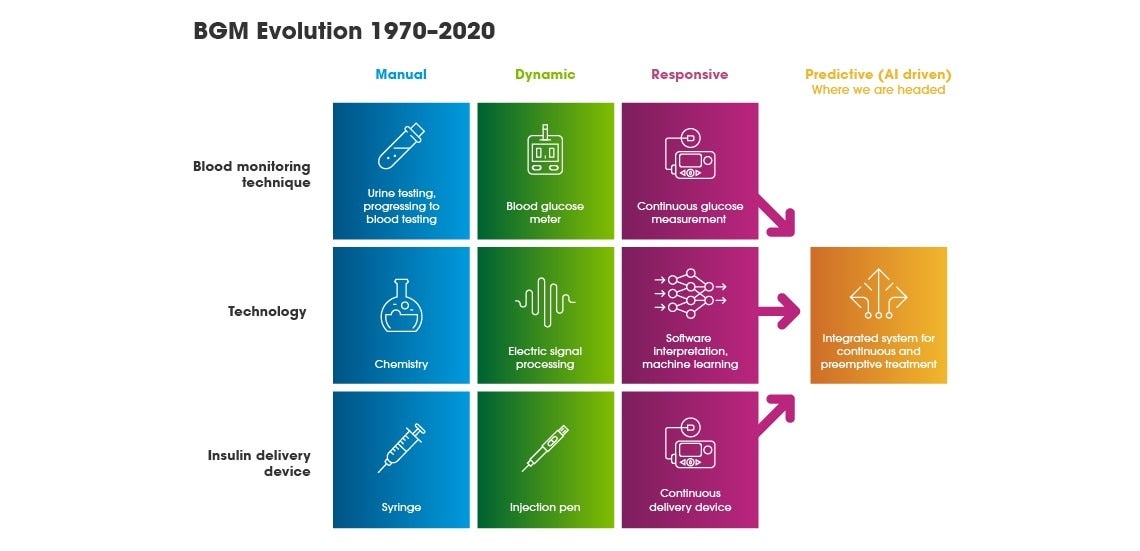

Blood glucose monitoring started as a simple urine sugar screening test. Gauged by the human eye, this method yielded inconsistent readings and diagnoses. It wasn’t until the 1970s that doctors began using testing strips to measure glucose in a blood sample. This same technology then moved from the hospital setting into the hands of patients. Today, sensor-based glucose meters, the gold standard, provide a digital reading and can transmit information to a smart phone or other connected device.

As a design-led manufacturer, we’ve been on the journey with diabetes companies for more than 30 years. In that time, we’ve helped BGMs evolve from:

- Inaccurate to accurate

- Basic to more complex

- Episodic to continuous

- Manual to automatic

We began by helping our customers bring reliable products to market affordably while also incorporating early advancements. The first portable blood glucose meter we manufactured was simple and met cost requirements for mass consumerization. We also proactively invested in technology development, even though the device included a customer-designed microcontroller and embedded software, so we would be prepared to meet consumer expectations.

As demand grew for connected devices that were less invasive and more accurate, we brought on engineers with expertise in medical device manufacturing and hardware and software design. This helped us partner with customers to develop advanced meters that added connectivity to insulin injectors and pumps.

Continuous monitoring and automated delivery for a new generation

Having produced more than 250 million BGMs over the past 25 years, we are currently collaborating with customers to develop a new generation of devices with continuous glucose monitoring (CGM) capability. These devices track glucose 24 hours a day through a sensor under the skin and transmit data back to a receiver or connected device.

With CGM, patients receive real-time data to proactively monitor their blood sugar. For patients on an insulin pump, CGM devices could eventually integrate continuous monitoring with automated insulin delivery.

Key benefits of CGM:

- More patient choice

- Less need for manual intervention

- Easier and more effective daily management of diabetes

BGMs go mobile

Once consumers could do almost anything on their phones — from paying bills to tracking their diet and exercise — they needed that simplicity when it came to their diabetes management. With our background and strength in connectivity solutions, we helped customers connect blood glucose meters to mobile phones.

When the mobile phone market began to drive the design of BGM displays, we responded quickly, developing touch screen displays that improved UI and lowered power consumption. Bolstered by a prequalified supply chain of approved display vendors, we introduced high-resolution displays with richer interfaces for new generation devices.

Understanding and innovating user experience

Consumers have a wide range of BGMs to choose from on the market, so we’ve made user experience a priority throughout our BGM development journey. We’ve taken the time to understand how consumers use BGMs and track their ever-changing needs through user research and human factors expertise.

We have continuously innovated based on key inputs such as:

- The need to operate a BGM with either hand, or with the limited dexterity that some diabetes patients have

- Design affordances that clearly communicate the orientation in which to hold the device and where to insert the test strip

- Intuitive button labels, so users can operate the device effectively and with minimal errors the first time without training

- The need to immediately decipher a clear BG reading number, notwithstanding a visual impairment

- Forming a quick understanding of how a new reading compares to the previous reading, and whether blood sugar is rising or falling

- Noticeable low battery warnings and design features that help users easily change batteries when needed

Mobilizing cross-industry expertise

Another way to make meaningful advancements in medical products like BGMs is to integrate technology expertise from other industries. We drew from our expertise in connectivity to embed Bluetooth into BGMs. Since we were already able to perform custom antenna designs and RF simulations to optimize signal transmission, we could develop radio interfaces for BGMs much faster.

Connectivity enhancements create a domino effect of new benefits. BGM data sent to a smartphone includes an electronic logbook. When paired with an app, this data can improve the user experience and the accuracy of records without adding extra costs at the device level. It also helps support the development of smarter predictive algorithms, which can in turn improve the management of diabetes and provide useful insights straight from the smartphone.

While there’s still progress to be made, the move to mobile devices is here to stay. We’re focused on integrating enabling technology into BGM technologies to increase their capability, usability, and functionality.

Manufacturing technologies to speed production

As demand for technologically enriched devices grew over the years, manufacturing techniques needed to keep pace, especially automation. Manufacturing technologies have historically been our core business. We’ve supported BGM companies with advanced engineering and manufacturing capabilities, helping them build and ship products around the world.

Robotic arms now handle the devices throughout the assembly line and interconnect key manufacturing processes. Highly automated test equipment ensures that the product complies with medical specifications. Meanwhile, data analytics from the machines shows how the equipment is performing and flags needed maintenance. Our traceability system, deployed in the production line, collects materials and test data that become part of the electronic device history records.

Our automation and lean practices:

- Improve process reliability

- Reduce production time

- Greatly increase line capacity by keeping running operating costs low

An integrated, affordable ecosystem

The evolution of blood glucose meters over the last 50 years has been essential to improving the treatment of diabetes. New AI enhancements and the widespread adoption of CGM devices together promise a future of even greater adherence.

But issues of affordability, accessibility, and security all threaten to complicate its arrival. Though CGM technology received FDA approval 20 years ago, only one out of four patients living with diabetes in the U.S. (of the nearly 7 million) actually uses it. Cost and access are the largest barriers. The increased collection of patient data also presents issues of cybersecurity and patient data privacy. For these reasons, standard blood glucose meters may continue to be a common choice, especially in developing markets.

Looking to the not-too-distant future, diabetes management can become an integrated ecosystem that includes sensors, apps, AI, drug guidance, and overall health monitoring. Such an ecosystem requires a simultaneous focus on improving outcomes for patients and decreasing cost. As a starting point, we are currently designing technologies that will extend the life of the sensor patch used in CGMs.

Partnering to ensure tomorrow’s products meet user needs

As our customers continue to transform their products, we’ll continue to support them. We’re at the ready with design, engineering, power management and connectivity expertise, all backed by our global reach and supply chain and powered by vertically integrated manufacturing excellence. We look forward to being involved as the next 50 years unfold.