What do you see when you look at a sensor?

If you’re a healthcare professional, you might appreciate the accuracy of a blood oximetry measurement. In a smart factory, a sensor could alert you to irregular vibrations, triggering a part replacement order and sparing you costly downtime. Maybe you’re seeing the distance between your car and the curb while driving — or the temperature of your next meal as it cooks.

When we look at sensors, we see the building blocks for intelligent products, improved experiences, and a better world. Across industries, technology trends such as miniaturization, sensor fusion, and low-power silicon are transforming the quality, functionality, and sustainability of intelligent sensor performance.

By choosing and integrating the right sensor technologies with local computing engines and connectivity solutions, you can maximize your next product’s efficiency, safety, and precision, no matter your industry.

From physical measurement to digital precision

With a reliable flow of instantly available information, your product can trigger critical responses — and improve its own processes. Sensors set those responses in motion by collecting analog physical measurements from their environment and connecting them to a processing unit. The processing unit interprets raw data locally and extracts relevant information to be sent to the cloud. This creates a digital representation of relevant metrics.

Miniaturize to meet market demand and enhance quality

The rise of 5G connectivity and the proliferation of IoT devices brings wireless sensing products that are both lightweight and small. Miniaturization technology can help you meet the demand for more compact and more mobile devices that process massive amounts of data.

As an example, Deloitte estimates that the market for connected medical devices will grow from $14.9B in 2017 to $52.2B in 2022 in an effort to reduce costs. Remote monitoring devices with miniaturized designs are key to that effort. Hospitals can send patients home earlier by giving them wearable devices that monitor heart rate and temperature.

By applying miniaturization technology to sensing systems, you can build more intelligence into smaller products. Take a voice-enabled virtual assistant, such as Google Home or Amazon’s Alexa. By using MEMS technology to create microphones as small as 1 mm x 1 mm, up to eight can fit into one product. These microphones are not only smaller, but highly sensitive, working together to identify the direction of sound and reduce background noise.

Tiny product design calls for quality assistance

Creating products with miniaturized designs is no simple task. Single analog sensors have been replaced with digital ones that have internal computational power, improving the complex data management in your product with unprecedented efficiency. You need to select the smallest silicon packages while interconnecting very small devices with small boards.

Strengthen data outputs with sensor fusion

Increased sensor speed makes more data points available, and improved fusion algorithms bring more accurate information. With better data points, you can create a clearer and more reliable digital representation of your product’s performance for faster, more precise automated responses. Understanding how different sensors can work together is another way to create the strongest, most reliable data output. With sensor fusion, you can combine different, correlated data streams to improve digital sensor measurements.

A wearable device might read a person’s heart rate with an optical sensor. However, wrist movement interferes with the quality of that sensor’s reading. Using an accelerometer sensor to detect wrist movement improves the measurement of the optical sensor.

Lower power consumption and extended product performance

Finally, to maximize the battery life of your product, you need to consider — and optimize — the entire power architecture. That includes power consumption stemming from the sensor, the processing unit receiving data from the sensor, and an additional chip that transfers the data (for example, via Bluetooth).

Processing collected data locally, close to the sensor, expends less energy than sending raw data that needs interpreting to the cloud. As an example, in a low power architecture, sensors might measure room temperature every few seconds, but report data to the cloud at different rates, depending on data stability. For example, the sensor could trigger an immediate notification when there’s a temperature change or at longer intervals if there are no major updates to report.

Partner for a richer experience with sensors

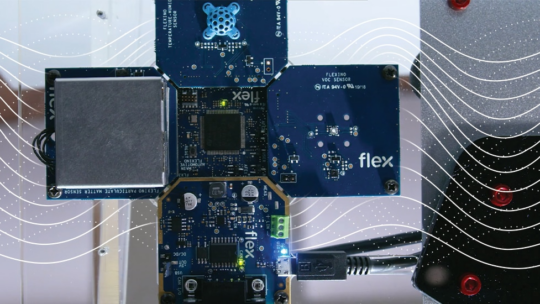

We can help you imagine and execute new applications using our design and manufacturing expertise in miniaturization, sensor fusion, and low power consumption.

Connect miniaturized components in your design and manage multiple silicon dies in the same package using our expertise in microelectronic packaging and system-in-package (SiP). And don’t let the data complexity of sensor fusion stop you from enhancing your product. Our sensor modules help you consolidate multiple outputs and simplify data processing.

Finally, how you design and integrate sensors can make a difference in power consumption. We can help you integrate the latest, ultra-low power silicon for sensors. Or, create battery-free products using our reference design for energy harvesting.

See new possibilities in sensors

From connected cars to remote patient care, everyday appliances, and the factories that manufacture them, we’re here to help you see new possibilities in sensors.

Learn how we can help you maximize the intelligence of your next product with sensors