A shift in automotive technology

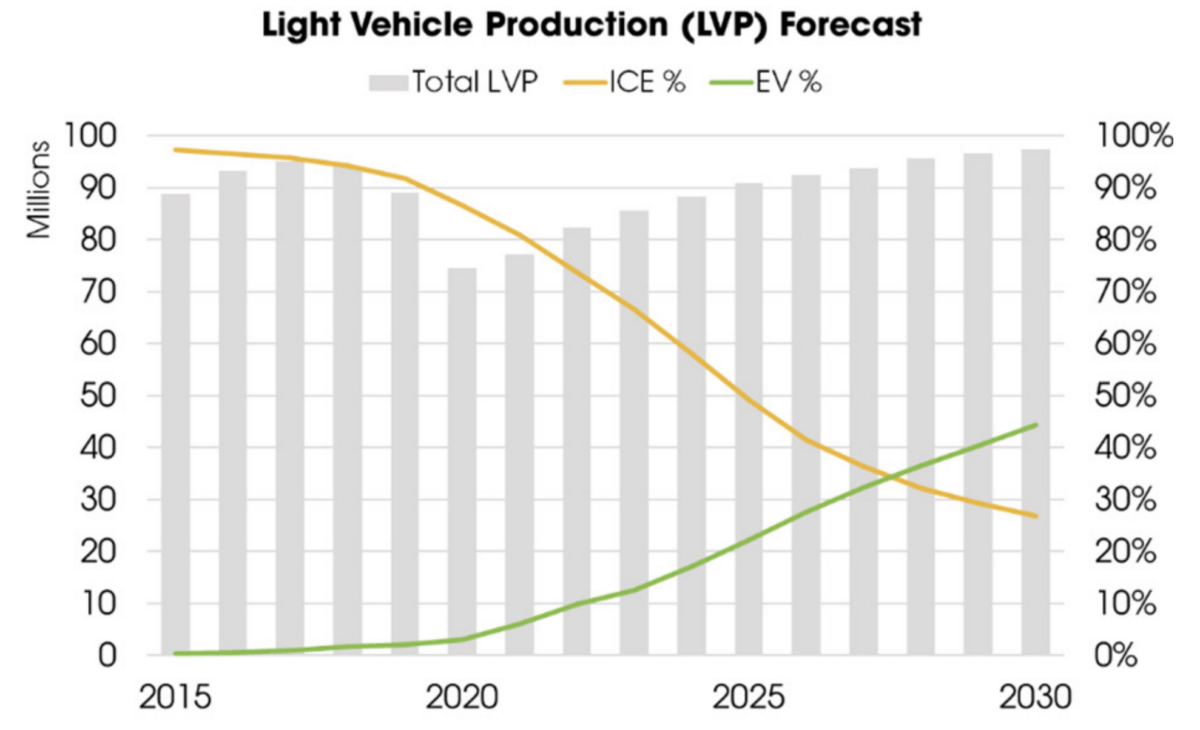

In the last few years, the automotive industry has experienced a significant and historical shift. The paradigm shift from Internal Combustion Engine vehicles (ICE) to Battery Electric Vehicles (BEV) has increased dramatically, and we have passed the inflection point in mainstream BEV adoption.

BEV production is expected to overtake ICE by 2027. Source: S&P Global Mobility, May 2023

Accelerate your BEV differentiation and supply chain efficiency

As more BEVs hit the market every year, OEMs are aggressively working to differentiate against their competition, drive lower costs, and better manage their supply chains. At Flex, we monitor these complex market dynamics continuously and diligently work to increase value for our customers by providing exactly what they need, how they need it — all while keeping an eye on future risks and opportunities.

Our flexible and ecosystem-first engagement model allows customers and partners to leverage our high volume manufacturing lines, established supply chain relationships, and expert design capabilities. We do this through direct engagement with our customers and continuous internal development alongside rigorous benchmarking and market research.

Our goal is to provide high value, reliable solutions with high power densities and efficiencies, from standalone products to complex integrated systems. Flex’s global manufacturing scale and broad supply chain network provide customers the flexibility to quickly adapt to rapidly changing dynamics and decrease time-to-market at this critical phase in BEV acceleration. We are strategically positioned across the globe, with regional power electronics operations in Europe, North America, and China. This strategy enables a targeted approach for each region, so Flex can serve our customers and meet their specific needs.

Our key design objective is to create platform architectures that enable high technology reuse despite evolving market requirements. This way we enhance material sustainability in collaboration with our suppliers and accelerate the development cycle for new products.

— Jan Riedel, VP, Power Electronics Engineering

A trusted partner for manufacturing and design services

Flex is an experienced, reliable, and global power electronics partner with expansive expertise in both manufacturing and design services. Our strong 50+ year foundation in electronics manufacturing brings a unique perspective unlike any other Tier supplier. By complementing manufacturing with design support, we can increase our value-offering to accelerate our customers’ time to market.

We have actively supported power electronics developments for over 15 years, starting with an Energy Recuperation Module concept in 2008. This concept directly informed how we approach design developments for our DC/DC converters today and helped us build expertise for adjacent power electronics products.

This includes both low voltage and high voltage designs, such as our latest combo unit which integrates a high voltage DC/DC converter and onboard charger into one system, optimizing design for size, weight, and cost. We also harness our considerable know-how to help improve customer designs for inverter PCBAs and battery management systems, with a focus on design-for-manufacturing and design-for-cost.

Pioneering the future of BEVs with industry-leading solutions

Building on our deep automotive power electronics experience, we will continue to innovate and drive growth as the industry evolves. We remain actively engaged with many global OEMs to support their new BEV platform architectures, ensuring that our products will provide the highest value through best-in-class features, material sustainability, efficiency, and quality at a competitive price.

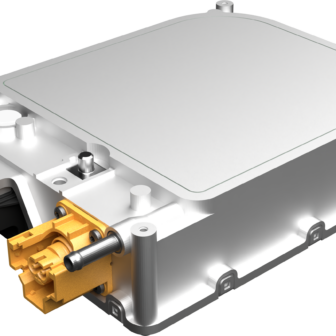

DC/DC Converter

Voltage: 400-800V

Power:3.6kW

Efficiency: 96%

Bi-directional: Yes

Safety rating: ASIL D

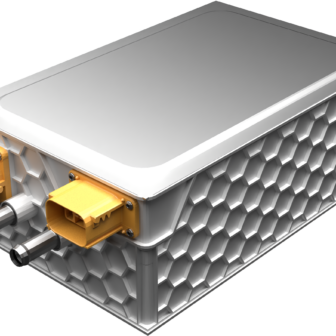

Onboard Charger

Voltage: 400-800V

Power: 11-22kW

Efficiency: 95%+

Bi-directional: Yes

Safety rating: ASIL C

Combo Unit

Voltage: 12V-800V

Power: 3.6kW; 11-22kW

Efficiency: 95%+

Bi-directional: Yes

Safety rating: ASIL C

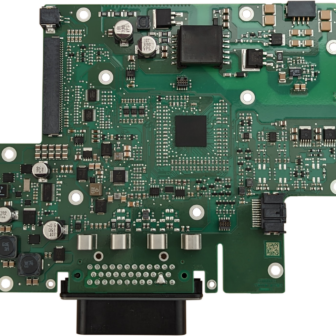

Inverter and BMS

Joint design

and manufacturing

of PCBAs