Intelligent visibility for greater insights

A report from Accenture states that “if there’s one key lesson businesses have learned over the past few years, it is that supply chains need to be much more resilient,” before going on to identify intelligent visibility as a key to resiliency.

Companies can build new capabilities that 1) help them assess where they’re most vulnerable; and 2) enable them to see exactly what is occurring across their extended supply chain.

— Accenture Report, The benefits of supply chain visibility

Indeed, companies seeking to improve their supply chain performance need to first understand what is happening. In a world where challenges are becoming more severe and ongoing—whether from geopolitical turmoil, tariffs, component shortages, or weather events—it is crucial that companies constantly monitor their supply chains to identify emergent risks and identify opportunities for improvement. The volume of data to digest is staggering, which is why advanced digital supply chain tools are the key to achieving true visibility. These tools can help companies rigorously evaluate, manage, and make informed decisions about their supply chains.

At Flex, we invest in technological innovation, modeling capabilities, and real-time visibility to help our customers anticipate and resolve supply chain issues before they impact their business. We also prioritize sub-tier visibility and have implemented tools to address this critical need, as disruptions of all kinds can happen deep within a supply chain network.

Our cloud-based, intelligent software platform integrates feeds from over 200 sources, helping customers turn insights into actions to navigate any crisis. The tool provides data visualization dashboards that enable real-time supply chain management, so users can easily identify any issues causing friction within seconds.

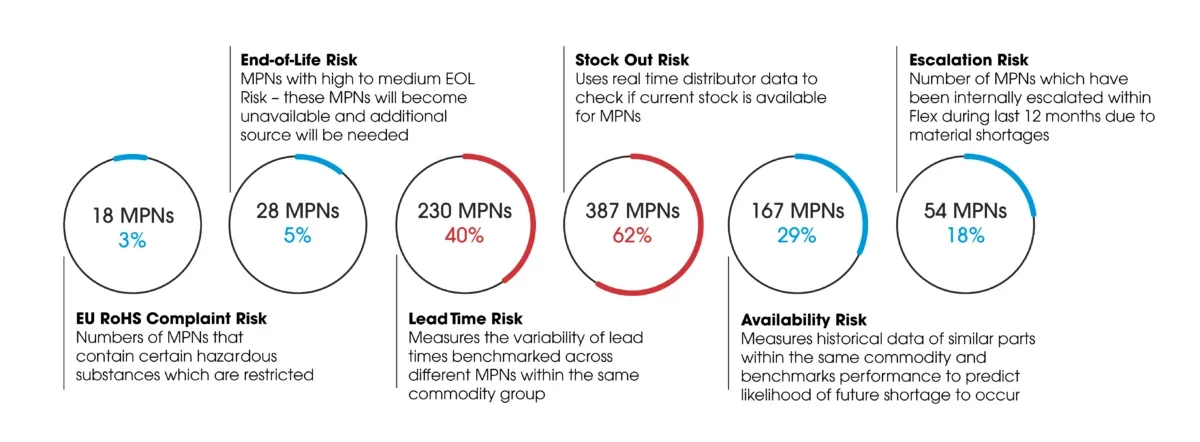

Our automated analytics application provides insights into the part level, allowing companies to identify supply chain risks early in the product lifecycle. The tool automatically assesses quotes, generates reports of potential risks, and provides recommendations to help companies implement risk mitigation strategies early with clear, quantifiable, and actionable insights.

Improving supply chain visibility with artificial intelligence (AI) and machine learning (ML)

At Flex, we help a diverse array of customers proactively assess risk early in their product lifecycle, giving them visibility into potential issues before production begins. To deliver early visibility and insights, we developed a proprietary analytics application, Flex Pulse Risk Management, that employs artificial intelligence (AI) and machine learning (ML).

The automated Risk Management report provides part level insights for a product’s bill of materials (BOM) across various risk factors. For example, from November 2022 to November 2023, we had Risk Management analyze 1,200 new products. Each BOM contained an average of 250 components. With improved visibility, Risk Management was able to identify opportunities for overall product risk reduction by 16 percent.

Risk Management report example

Assessing and mitigating supply chain risk in the automotive industry

Flex Pulse Risk Management has been critical in helping customers assess industry-specific risks by comparing risk profiles for similar products across multiple end markets. By analyzing supply chain trends of complex compute units for both automotive and data centers, Risk Management helped uncover that the automotive industry is:

- 25 percent more likely to experience out-of-stock components

- 15 percent more likely to see future component shortages

- 10 percent more likely to experience long lead times

Flex Pulse Risk Management tool outcomes for ~2,500 products in Quote stages

from last two years (all business units)

With this information, we were able to use our experience with data center supply chains to identify potential risk mitigation strategies—including regionalization, multi-sourcing, industry-wide collaboration, and supply chain digitization—that would help our automotive customers reduce overall risk and bolster supply chain resiliency for their complex computing products.