As far back as 2020, the World Economic Forum identified four durable shifts in manufacturing:

Agility and customer centricity

put at the centre of operations leading to faster recognition of customer preferences and corresponding adjustments of manufacturing flow at next-generation, small-scale modular plants

Supply chain resilience

as a competitive advantage requiring connected, reconfigurable n-tier supply ecosystems, regionalization and overall higher level of customization

Speed and productivity

attained through increased levels of automation and workforce augmentation, increasing safety and competitiveness in a society where continuous reskilling and mobility are becoming the norm

Eco-efficiency

as a must-have to stay in business and ensure compliance with an increasingly complex

regulatory landscape

They described the four shifts as “proving increasingly relevant in light of unprecedented challenges” and “key to organizations’ sustainability in the face of disruption.” Today, these four shifts remain as relevant as ever for companies to be competitive, resilient, and responsible as we move into the future.

In this paper, we walk through five use cases at Flex that leverage different toolsets, systems, business models, and approaches that address one or several of the durable shifts transforming the manufacturing industry. By leveraging advanced manufacturing technologies combined with innovative, human-centric, and data-driven decision-making, manufacturers can capture all four shifts: agility and customer centricity, supply chain resilience, speed and productivity, and eco-efficiency.

Data analytics and the ability to make informed, timely decisions are crucial to remain competitive, resilient, and agile in today’s ever-evolving business landscape. At Flex, we recognize that data collection and analysis serve as the foundation for every system. We also recognize that leveraging advanced analytics results in optimized manufacturing processes and other systems-wide improvements so that we can meet our customers’ volume needs while maintaining world-class product quality.

Using industrial sensors, manufacturers can measure various parameters such as vibration, humidity, temperature, pressure, and video and optics data. This wealth of information provides valuable insights into manufacturing operations and enables real-time data-driven decision making. Moreover, Internet-of-Things (IoT) platforms and data management solutions can be used to incorporate advanced analytics, machine learning, and failure analysis, among other capabilities. At Flex, we take this holistic approach to embedding advanced analytics into the manufacturing process, so that we can harness the full potential of the digital manufacturing ecosystem.

To realize this vision of hyperconnected value networks, manufacturers must employ a large variety of data‑and‑analytics applications, such as predictive maintenance, advanced robotics, and tracking and tracing in supply networks. The underlying data assets are the lifeblood of these applications.

This data can:

- Provide actionable insights by discerning patterns from data through human analysis of reports and dashboards.

- Predict future outcomes for business stakeholders to act upon, using advanced analytics on historical data.

- Enable self-optimizing systems that take autonomous action through self-learning self-steering algorithms, with input from historical and real-time data.

At Flex, we deliver real-time analytics and control through a comprehensive approach to the industrial IoT ecosystem. By investing in an end-to-end ecosystem that encompasses data collection, advanced analytics, and real-time control, we drive overall efficiency gains, optimize manufacturing processes, and help our customers succeed.

Factory virtual operator increases speed and productivity in advanced manufacturing

Our site in Althofen, Austria is a high-mix low-volume facility serving customers with a portfolio of hundreds of highly complex projects. This means that in any given month, the site sees a monthly average of 900 changeovers.

That level of complexity can be difficult and time-consuming for human operators to manage, so the team sought to improve these processes by implementing a 24/7 Line Stop Assistant we named LISA. LISA is a propriety, virtual operator system with real-time access to all the data sources related to production lines.

LISA uses this data to halt misconfigured production lines, alerting the shop floor team to resolve errors before they get further downstream. It also identifies line operators and ensures that they are properly trained before configuring a line.

Since LISA’s initial rollout in 2019, the Althofen site has seen improvements in changeover metrics by reducing:

Increasing accuracy and productivity for PCBA with AI for predictive maintenance

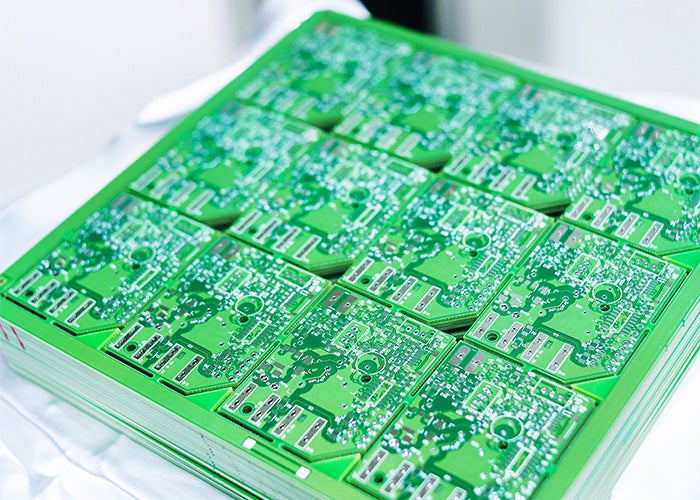

Flex produces thousands of printed circuit board assemblies (PCBAs) a month at our site in Zalaegerszeg, Hungary. PCBAs are necessary for all electronic products, making them a key element of nearly every customer design. With the complexity, quality, and volume that customers require, there is no room for error.

Additionally, if the cycle time of these machines is either too long or short, there is a possibility that a failure or other negative event will occur. This is why manufacturers must ensure that machines are behaving appropriately — and catch issues quickly when machines are not performing to standard. Many times, errors occur in a pattern, which can carry onto hundreds of units if not detected in time.

Traditionally, we leveraged advanced systems to collect data from the machines used for PCBAs, then analyzed the collected data to help better understand machine failures, maintenance, and anomalies during production. This meant that site operations were provided with insights after errors or issues had already happened — so preventative action was impossible.

In 2023, Flex implemented a more proactive approach that allowed us to quickly collect and assess granular data so that we could act before problems arose or worsened. We developed deep learning models using generative AI to analyze the vast amount of historical data to predict anomalies, maintenance, and failures with localization before they happen. This new approach resulted in:

20–30%

Line utilization improvement by reducing downtime during the PCBA process

~33%

Increase of line operator productivity

25–30%

Increase of engineering team productivity

According to McKinsey & Company’s Procurement 2023 report, “procurement leaders can combat volatility, inflation, and shortage and build resilience… by gaining transparency into the pressures they face,” and that “building an agile procurement function with stronger links to internal and external partners is the key to success.”

We’ve also implemented Flex Pulse® Risk Management, a tool that harnesses artificial intelligence and machine learning (AI/ML) technology to help our customers design risk out of a product’s bill of materials (BOM). With Risk Management, we collaborate with our customers to address supply chain risks and recommend mitigation options. The tool provides part-level insights at an early product lifecycle stage to avoid incurring larger negative impacts if risks arise in the product build or production stages.

The Flex Pulse® Risk Management report typically contains:

These powerful digital tools enable companies to comfortably navigate the shifting business landscape, reduce risk, and make data-driven decisions to sustain a more responsive, resilient supply chain.

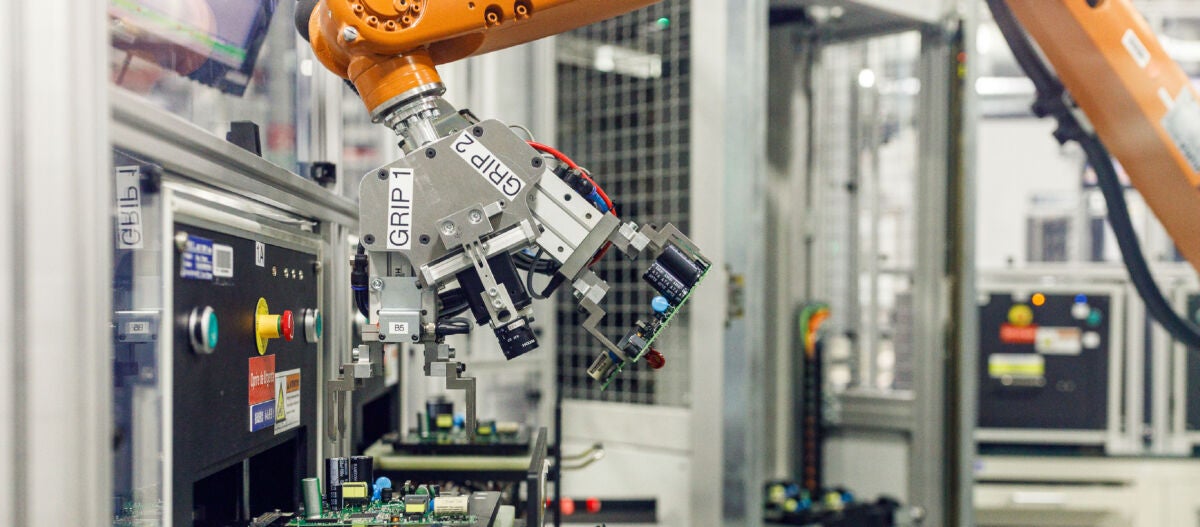

Realizing efficiencies and creating a safer, more inclusive work environment via automation and robotics

A Deloitte study stated that “autonomous robots can be used to improve the speed and efficiency of routine operations, particularly in warehousing and manufacturing spaces; work side-by-side with humans for added efficiency; and reduce the risk of employee injury in dangerous environments.”

In manufacturing, automation and robotics — including collaborative robots (cobots) and autonomous robots (AMRs) — can come together to optimize production while making the workplace safer and more inclusive. The use of robotics in tight spots, for example, frees human workers from dangerous or unpleasant tasks, while a robot that can lift heavy objects effectively removes the “ability to lift” requirement in many job description — enabling jobs to be filled by applicants with diverse abilities.

At Flex, AMRs are employed in advanced manufacturing warehouse facilities to bring supplies to automated manufacturing lines, move components from one location to another for the next steps, and transport the final product to the loading dock to be shipped to the customers. The robot operator assigns tasks, tracks its location, and responds to issues or obstacles via a tablet, smartphone, or computer. Data analytics are collected when the robot is operating and used to enhance performance and safety features for continuous improvement.

Emerging autonomous solutions (such as cobots mounted on AMRs) could help repurpose legacy infrastructure with enhanced technology.

— McKinsey & Company, December 2023 report on warehouse automation

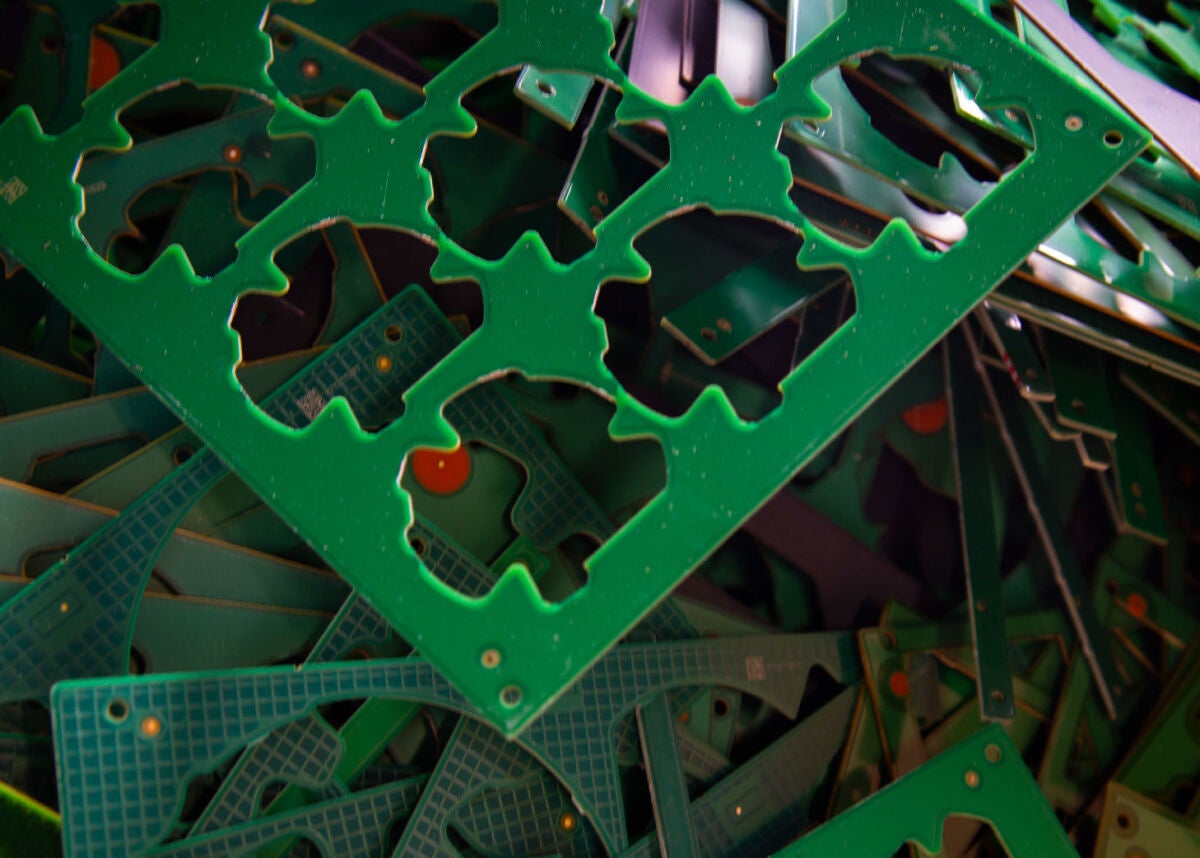

Achieving sustainability benefits through advanced manufacturing

Another rising area of focus for companies is sustainability. A report by Gartner stated that “organizations are making aggressive and strategic sustainability goals to improve their brand reputation, ensure regulatory compliance and improve resource efficiencies.” The same report cited survey data demonstrating the top benefits to be derived from sustainability programs by 2025, including: increased company brand/reputation, improved resource efficiency, innovation and new products, improved customer satisfaction, and better risk management.

There’s a sense of urgency in prioritizing sustainability as consumers, investors, and regulatory agencies continue to hold the brands they support to a higher standard. And while the benefits are myriad, companies may struggle with the learning curve and investments required to achieve sustainable design, sourcing, manufacturing, fulfillment, and after-market services.

At Flex, our sites around the world leverage advanced manufacturing technologies and solutions to not only deliver better business outcomes for our customers, but to also advance sustainable manufacturing and production.

By digitizing their circular economy system, the site in Sorocaba also was able to better measure sustainable impacts, including a 41% reduction in scope 1 and 2 greenhouse gas emissions as well as a 30% reduction in water consumption.

Conclusion

Organizations at the forefront of manufacturing’s transformation recognize that addressing the four durable shifts — agility and customer centricity, supply chain resilience, speed and productivity, and eco-efficiency — is what will enable them to design, build, and deliver innovative, high-quality products at scale.

At Flex, we continually enhance our advanced manufacturing capabilities by investing in a focused portfolio of advanced manufacturing technologies and solutions — including simulation, automation, robotics, digitization, and additive manufacturing—while also embracing new business models and empowering our workforce. Doing so fuels our flexible, global manufacturing and increases efficiency and quality. Embracing advanced manufacturing in all its facets allows us to meet our customers’ time-to-market, resiliency, sustainability, and end market requirements.

Download the white paper